针对固体火箭发动机恶劣环境下的高温燃烧测量问题, 提出了利用辐射光谱法来开展固体火箭推进剂燃烧温度在线测量的方法, 采用200~1 100 nm光纤光谱仪测量了高压实验燃烧器下固体火箭推进剂燃烧火焰辐射光谱, 总结了其光谱特性, 并基于普朗克定律和光谱拟合方法获得了相应的推进剂燃烧温度, 这对固体火箭推进剂燃烧诊断与燃烧机理研究具有重要的参考价值。

For the high combustion temperature measurement in harsh environment, the radiation spectroscopy method was proposed to realize the online measurement of combustion temperature of solid rocket propellant. The radiation spectrums in the range of 200~1 100 nm of solid rocket propellant flame in high pressure experimental combustor were obtained by fiber-optic spectrometer. Their representative characteristics were summarized, and the corresponding combustion temperature was determined by the Planck radiation law and the spectral fitting method. The paper provides important reference for combustion diagnostics and mechanism of solid rocket propellant.

Owing to high calorific value, excellent mechanical properties, wide adjustable range of burning rate and steady storage stability, composite solid propellant is widely used as power source of rocket and missile[1, 2]. It is made from mechanical mixing, pouring and solidifying of polymeric binders, solid oxidizer, metal powder and catalyst. The thrust of engine derives from recoil of high temperature burning gas of composite solid propellant. During this process, combustion temperature is one of the most important energy parameters for composite solid propellant[3]. However, due to high temperature and pressure, multiphase flow and multi-fields couplings, the combustion of composite solid propellant is an exceedingly complex physical and chemical process. Thus, the combustion temperature measurement is more difficult in this harsh environment[4]. The traditional thermometry, such as thermocouple and thermal resistance, cannot satisfy the demands of combustion temperature measurement of composite solid propellant. Especially the combustion temperatures of several latest high energy solid propellants has already far exceeded the measuring ranges[5]. At present, many laser combustion diagnostic techniques, such as Coherent Anti-stokes Raman Spectroscopy (CARS), have been attempted to measure the combustion temperature of solid rocket propellant. But there still exists some problems: strong radiation, scattering attenuation of solid particles in the flame and influence of high pressure on spectral lines[6].

Compared with the laser diagnostic techniques, the radiation thermometry only determines the self-radiation to obtain the temperature of flame, which provides direct information of heat transfer, and has better measurement stability in strong vibration environment. Thus, radiation thermometry is a powerful tool for high temperature in situ measurement of complex flame due to its advantages of fast time response, high reliability, wide measurement range and non-intrusive[7]. Especially for the combustion of composite solid propellant, a very large amount of solid metal particles are burned and emits stronger light, which causes strong noise for the laser diagnostic techniques, but ensures the radiation signal with enough Signal Noise Ratio (SNR). In the past two decades, colorimetric, single-wavelength, dual wavelength, multiple wavelength/waveband and spectroscopy methods were proposed to improve the measurement accuracy[8, 9, 10, 11]. Moreover, the temperature field can be reconstituted based on radiation thermometry and imaging method[12].

With a rapid development of spectroscopy, radiation spectroscopy is considered as one of the most potential diagnostic techniques for composite solid rocket propellant because of its advantages in harsh environment, and it can also provide more information about combustion process based on spectral characteristics.

The principle of radiation spectroscopy is the Planck radiation law. It describes the relationship between radiation intensity (E) with the temperature (T), wavelength (λ ), and surface condition

where C1 and C2 are the first and second radiation constant, 3.742× 10-16 W· m2, 1.438 8× 10-2 m· K, respectively; ε (λ , T) is the emissivity of the medium. As the flame can be considered as graybody approximately, ε (λ , T) can be seen as a constant ε (T) in different wavelength.

Once the radiation spectrums are obtained, temperature can be determined by parameters fitting method using the least square method[11]. The objective function is fitted as follows

where ε '=lnε , t=1/T. When f gets minimum value, the corresponding value of T is measurement result.

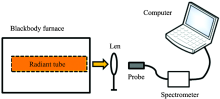

However, the Charge Coupled Device (CCD) of fiber-optic spectrometer has different response to different wavelength light. The corresponding absolute radiation intensity of radiation spectrum should be calibrated by blackbody furnace (Fuyuan, HFY-203B, ε =0.98~0.99, 773~1 523 K) as shown in Fig.1. When the furnace makes temperature steady at the set value, the emitting light is coupled into optical fiber. And the spectrometer measures the radiation spectrums of blackbody radiation which can be calculated by equation (1). Thus, it provides the standard values to estimate the radiation intensity in different wavelength.

Defined response coefficient of specific spectrometer (kλ ) at the specific temperature as follows

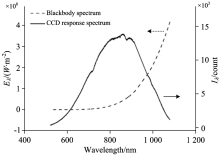

where Eλ is the theoretical value calculated by equation (1); Iλ is the response of spectrometer. The theoretical radiation and experimental spectrum (measured by Ocean Optics, HR4000, 200~1 100 nm) of blackbody at the temperature of 1 473 K is shown in Fig.2. Thus, the response coefficients in different wavelength can be obtained by equation (3). Once the radiation spectrums are measured, the absolute radiation intensities can be calibrated by these response coefficients to determine the temperature of flame.

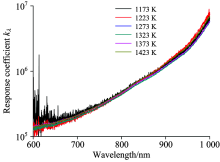

According to above calibration method, the response coefficients at different temperatures are obtained. For the response near the ends of the range of 200~1 100 nm is very little and the response coefficients has a large span, the selected range of fitting spectral data has great influence on measurement accuracy. The response coefficients of different temperatures in the range of 600~1 000 nm are shown in Fig.3. The curves become more stable as temperature increases due to stronger radiation intensity. Considering stability and roughly equivalent value of response coefficients in the selected range, the spectral data in the range of 700~900 nm is appropriate to determine temperature.

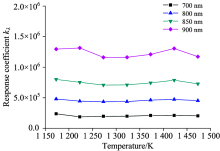

Additionally, the response coefficients vary with the temperature. The iterative method is required to solve the optimized temperature in radiation spectroscopy. As the target temperature is unknown, even far exceeds calibrated temperature range, this iterative method is low-efficient. However, as shown in Fig.4, the response coefficients of the specific wavelength at different temperatures are approximately constant in the range of 700~900 nm, which is also shown in Fig.3. Thus, the response coefficients at 1 473 K can be effectively acted as calibration coefficients in radiation spectroscopy.

Radiation spectroscopy has been demonstrated to measure combustion temperature of kerosene blast burner. The measurement results of different compressed air flow conditions (0, 2.0, 2.5, 3.0 L· min-1) are shown in Table 1. Compared with thermocouple, the relative deviation is less than 5%.

| Table 1 Comparison of temperature measurement results based on radiation spectroscopy and thermocouple |

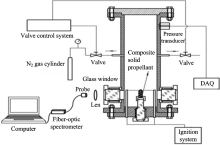

As shown in Fig.5, the experimental system is composed of high pressure combustor, pressure control system, ignition system and radiation spectroscopy measurement system. The composite solid propellant specimen (size: 5× 5× 50 mm, chemical formulation: AP/18%Al/HTPB) is clamped in the center of combustor. The high-temperature ignition wire threads through propellant specimen and connects the two electrodes. The combustor is filled with N2 to keep the pressure at actual working situation. When the specimen is ignited at the set pressure (3.0 MPa in this paper), the measurement probe collects the light of flame through the glass window. And the light is transmitted to fiber-optic spectrometer (Ocean Optics-HR4000, integral time: 5 ms) to measure the radiation spectrums. The experiment lasts about 3~4 seconds.

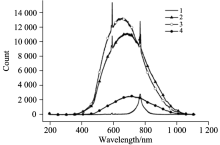

Four typical radiation spectrums of combustion flame are shown in Fig.6. They are four processes of composite solid propellant respectively: the beginning of ignition (1), steady-state burning (2 and 3), and burning out (4). The radiation spectrums of composite solid propellant flame have strong and continuous features in this wavelength range (200~1 100 nm), and they are similar to the radiation spectrums of the blackbody furnace. With the development of combustion process, the radiation intensity becomes stronger gradually. During steady-state burning, the radiation remains at a high intensity. When the propellant is burned out, the intensity weakens rapidly and keeps a certain value for a short time, then disappears.

The radiation spectrum of composite solid propellant flame is the combined emitting effect of high-temperature solid particles and gas. The spectral feature in visible range is continuous, but in infrared range is zonal because of the absorption of gas molecules. Duing to the radiation characteristics of solid particles in 200~1 100 nm range, the flame of composite solid propellant can be considered as gray body, and the measured results are the temperature of solid particles.

As shown in Table 2, the temperature are determined from these spectrums in the wavelength range of 200~1 100 nm by using radiation spectroscopy. At the beginning of ignition, the strong lines of metal flame color appears immediately. For the temperature is still low, the temperature can’ t be analyzed by using radiation spectroscopy.

| Table 2 Measurement results based on the typical radiation spectrums |

Fig.6 also shows that the changes of position of radiation spectrums peak are related to temperature. The wavelength of radiation spectrum peak shifts towards the shorter as the temperature increases, which satisfies the Wien displacement law as follows

where λ m is the wavelength of radiation peak. The rapid thermometry can be proposed based on peak of radiation spectrum

in the follow-up work.

As shown in Fig.6, there are several obvious emission peaks detected near 592.1 and 768.4 nm. From NIST Atomic spectra database, they are iron and aluminum atomic emission lines respectively. At the beginning of ignition, aluminum powder is burning rapidly and the flame color is very bright. The little quantity of heat generated during ignition cannot raise the temperature immediately. Thus, there is only an obvious and strong aluminum atomic emission line in No.1 radiation spectrum. With the development of combustion process, the solid particle and gas species are heated rapidly and emit continuous radiation. At the same time, the iron (mainly from iron-based catalyst) and aluminum atomic emission lines overlay onto the continuous radiation. Hence, the radiation spectrums during steady-state burning are formed as No.2 and No.3 spectrums. When the propellant is burned out, the violent chemical reactions stops, and the electron transition in the atom cannot be stimulated. For the heat cannot lose completely in a short time, the temperature is still high, but there is no atomic emission line in No.4 spectrum. These radiation characteristics of flame have important references to represent combustion process, reveal the fundamental mechanisms of combustion and improve the efficiency of energy utilization. However, it is worth mentioning that the discontinuous and strong metal atomic emission lines should be eliminated in the fitting process to determine the temperature.

Moreover, compared with intensities of No.2-4 spectrums (Fig. 6), when the temperature is roughly equivalent, the intensity strongly depends on concentration of solid particles. During the steady-buring state, No.2 and 3 have similar intensities due to the almost same solid particles concentration. When the propellant is burnied out, the solid particles spread in the combustor. Thus, the intensity of No.4 spectrum reduces dramatically, but the temperature is still high.

In conclusion, radiation spectroscopy method and its calibration method are propose to realize the online measurement of combustion temperature of solid rocket propellant. And the representative characteristics of radiation spectrums of solid rocket propellant are discussed and explained in detail. This study can provides important reference for combustion diagnostics and mechanism of solid rocket propellant.

The authors have declared that no competing interests exist.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|