二噁英是一类含氯挥发性有机污染物, 具有环境持久性、 生物蓄积性和长期残留性等特性, 可造成致畸、 致癌和致突变等危害。 铁矿烧结过程中含氯前驱物在碱性环境下通过Ullman反应或经飞灰中某些催化性成分催化生成二噁英; 碳、 氢、 氧和氯等元素可通过基元反应“从头合成”(de novo)二噁英, 是二噁英最主要的排放源之一。 物理吸附技术仅能实现污染物由气相向固相转移, 加重了飞灰处理负担, 并存在特定温度条件下(250~350 ℃)二噁英再生风险。 催化降解技术能彻底矿化有机污染物, 生成CO2, H2O和HCl/Cl2, 是一种避免二次污染高效节能、 成本较低的方法。 但由于传统催化剂活性温度区间较高, 无法达到烧结烟气末端温度。 选择合适的催化剂, 提高催化剂低温降解活性, 能实现低温、 高效催化降解烧结烟气中有机污染物的目标。 过渡金属Ce具有稀土金属的4f轨道配位效应和路易斯酸活性位点, 对有机污染物C—H和C—Cl键活化起到至关重要的作用, 掺杂过渡金属、 调整活性组分比例可进一步提高铈基催化剂的抗中毒性能和降解活性。 因此, 本文采用溶胶凝胶法制备Ce-V-Ti复合催化剂, 以氯苯为二噁英模型分子, 研究了不同活性组分比例对铈基催化剂降解烧结烟气中二噁英活性影响。 利用X射线衍射仪、 比表面积及孔径测定仪和拉曼光谱仪对催化剂进行表征, 研究Ce-V-Ti催化剂的相组成、 比表面积和分子结构, 并推测铈基催化剂的降解机理。 结果表明, 在实验室模拟烧结烟气气氛下, 反应条件为GHSV=30 000 h-1、 20%O2和100 ppm CB, 当Ce质量分数为15%、 V质量分数为2.5%时, Ce-V-Ti催化降解氯苯活性最高, 150 ℃能达到约60%转换率, 300 ℃能实现95%降解率。 催化剂载体与活性组分之间化学交互作用, 影响催化剂的降解活性。 通过光谱学分析发现, Ce-V-Ti催化剂XRD图谱主要为锐钛矿相的TiO2, 比表面积为95.53 m2·g-1, 孔容0.29 cm3·g-1, 孔径6.5 nm。 表面官能团主要为C—H基团和H—O官能团。 引入V作为Ce-Ti催化剂助剂, 促进了Ce元素固溶, 增加了催化剂表面氧空位, 有利于提升催化剂降解活性。 通过对催化剂机理分析, 认为反应物首先通过发生亲核取代而垂直吸附于催化剂表面, 再被活性组分Ce活化, 活化后氯苯分子被表面活性氧分解矿化。 同时, 过渡金属V的低价态氧化物发生氧化反应, 促进Ce的还原反应。

Biography: SHI Qi, female, (1988—), lecturer, School of Metallurgical Engineering, Anhui University of Technology e-mail: 13615556646@163.com

Dioxins are a group of chlorinated volatile organic pollutants (VOCs) with environmental persistence, biological accumulation and long-term residual properties. It can cause teratogenic, carcinogenic and mutagenic hazards. During the iron ore sintering process, dioxins can be catalytically synthesized from chlorine-containing precursors by Ullman reaction in the alkaline environment or by some catalytic components on the surface of fly ash. Besides, dioxins can be synthesized by de novo through elementary reaction. Iron ore sintering process is one of the most emission sources of dioxins. Physical adsorption technology can only remove pollutants from gas phase to the solid phase and increase the aftertreatment problem of fly ash. Besides, there is a risk of dioxins regeneration under 250~350 ℃. Catalytic combustion can be completely degradation dioxins into CO2, H2O and HCl/Cl2 over catalysts. It is an efficient, energy conservation and low-cost method to avoid secondary pollution. However, the working temperature of traditional catalysts is too high to the end temperature of the sintering flue gas. It is important to improve the catalytic activity at low temperature to achieve high efficiency catalytic combustion of VOCs from iron ore sintering flue gas. As Ce has the 4f orbital coordination effect and Lewis acid site, which plays a crucial role in the activation of C—H and C—Cl bonds in organic pollutants, the anti-chlorine toxicity and combustion activity of the catalystcan be improved by doping transition metal or adjusting the proportion of active components of catalysts. Hence, the effect of different Ce/V weight ratio of Ce-V-Ti catalysts prepared by sol-gel method were studied in this paper. Chlorobenzene was used as the model molecule of dioxins. The phase, specific area, molecular structure and functional groups of Ce-V-Ti catalysts were characterized by XRD, BET,XPS and FTIR. The results show that the catalytic activity of chlorobenzene over Ce-V-Ti catalysts with 15 Wt% Ce and 2.5 Wt% V can achieve CB conversion of 60% at 150 ℃ and 95% at 300 ℃ under the reaction conditions of GHSV=30 000 h-1, 20% O2 and 100 ppm CB. The chemical interaction between the barrier and the active component affected the catalytic activity of catalysts. According to the spectroscopic analysis, the XRD pattern of Ce-V-Ti catalysts was mainly anatase TiO2. The specific surface area was 95.53 m2·g-1, the volume of the pore was 0.29 cm3·g-1, and DBJH was 6.5 nm. Most of the functional groups on the Ce-V-Ti catalysts were C—H groups and O—H, which was expedited the adsorption and desorption of CB. The introduction of V as co-catalytic compositioninto Ce-Ti catalyst promoted the solid solution reaction of Ce element and increased the oxygen vacancy on the surface of the catalyst, which was conducive to improving the catalytic activity of the catalyst. Meanwhile, the oxidation reaction of V in low-price promotes the reduction reaction of Ce.

Dioxins are general of chlorine volatile organic pollutants (CVOCs) with 75 kinds of Polychlorinated Dibenzo-ρ -dioxins(PCDDs) and 135 species of Polychlorinated Dibenzo-ρ -dioxins(PCDFs). It has the characteristics of environmental persistence, biological chemicals, and long-term persistent with the harm of teratogenic, mutagenic and carcinogenic, and so on, which is regarded as one of the most toxic poisons on earth[1, 2]. In the iron ore sintering process, chlorine-containing precursors can be catalyzed to dioxins by Ullman reaction in the alkaline environment or by some catalytic components on the surface of fly ash. Carbon, hydrogen, oxygen and chlorine can synthesize dioxins by de novo through elementary reactions[3]. Without high-efficiency flue gas treatment technology for dioxins, iron ore sintering process has become the largest dioxins emission source. Therefore, it is an urgent issue to realize deep purification and emission reduction of dioxins fromiron ore sintering flue gas.

Lots of techniques have been developed for solving the release of dioxins from iron ore sintering flue gas. Among them, catalytic combustion is an effective method to complete mineralization of dioxins into CO2, H2O and HCl/CL2 at relatively low temperature[4]. Therefore, an effective catalyst is a key to flue gas treatment. Studies have shown that transition metal oxide catalystsare estimated to be an ideal choice for catalytic combustion of chlorine-containing organics with advantages of strong resistance to chlorine poisoning and cheap[5, 6, 7, 8]. Yu et al.[6] studied the catalytic combustion of PCDD/Fs over a variety of transition metal oxide catalysts and composite metal oxide catalysts V-containing in the laboratory. The results showed that the best activity of nanao-TiO2 based catalysts was VOx/TiO2 catalyst, andfollowed by CeOx, MnOx, WOx and MoOx loaded catalysts.Besides, composite metal oxide catalysts of VOX-CeO2/TiO2 also showed excellent catalytic CB conversion. Rare metal Ce has the 4f orbital coordination effect and Lewis acid site, which plays a crucial role in the activation of C— H and C— Cl bonds in organic pollutants[7]. The doping transition metal can improve the anti-chlorine toxicity and combustion activity of catalyst [6]. The selectivity and stability of catalysts can be improved by adjusting the proportion of active components of catalysts[8].

Herein, the comparisons of and characterization of Ce-V-Ti prepare with the number of Ce/V weight ratio by sol-gel method were carried out. Chlorobenzene was used as the probe reactant to study the catalytic activity of catalyst under simulating iron ore sintering flue gas. Then, a one-step sol-gel method was developed to form Ce-V-Ti catalysts with a mass ratio of Ce:V from 2:1 to 8:1. The catalysts were characterized in detail by XRD, TEM, BET, XPS and TPR and catalytic activity. In addition, the structure and morphology properties of the catalysts were investigated. The main goal of this study is to present an optimal mass ratio of Ce/V to prepare Ce-V-Ti catalysts with high catalytic activity and resistance to water and sulfur.

Ce-V-Ti catalysts were prepared by a sol-gel method. Ce(NO3)3· 6H2O ethanol solution was added to Ti[O(CH2)3CH3]4 ethanol solution with about 15 wt% ratio of Ce/(Ti+Ce+V) under stirring. Then the solution of NH4VO3 and oxalic acid (

Characterization by XRD, BET, XPS and FTIR was carried out. The phase structures of catalysts were analyzed by a German D8ADVANCE X-ray diffractometer (XRD) with CuKα radiation (CuKα =0.154 06 nm). The surface area and distribution of pore size were carried on an ASAP-2020 surface analyzer from Micromeritics, USA. X-ray photoelectron spectroscopy (XPS) was used to analyze the oxidation states on the surface of the CeO2-VOx-TiO2 catalysts with AXIS ULTRP, which using AlKα (1 486.6 eV) radiation as the excitation source (powered at 10 mA and 15 kV). FT-IR spectra were recorded at room temperature on a Fourier Transform Infrared. Spectrometer (FT-IR, Nicolet, 5DXC) in the 500~4 000 cm-1 range and a resolution of 4 cm-1.

Catalytic activity was carried out in a self-designed apparatus at atmospheric pressure of 100~400 ℃ (Fig.1). Ce-V-Ti catalysts were placed in a silica tube with 3 mm inner diameter. As dioxins are very highly toxic and hard to handle, chlorobenzene (CB) was employed to be model compounds to predicted the catalytic activity of dioxins over different catalysts. The CB containing feed stream to the reactor was carried by N2 and controlled by a flow controller with a typical GHSV (gas hourly space velocity) of 30 000 h-1. The reaction flue gas was composed of 16% O2 and 84% N2, and the CB concentration was set to 100 ppm to simulate iron ore sintering flue gas. The recent gases were analyzed under a given temperature by using an online gas chromatograph (GC) equipped with flame ionization detector (FID1) and SE-54 capillary column for the quantitative analysis the inlet and outlet of CB. During the CB analysis, the temperature of the column and detector of GC with nitrogen as carrier gas was set up as 100 ℃ and 150 ℃, respectively.

The conversion ratio of CB (η ) was calculated as follows

where, the CBin and CBout were the inlet and outlet concentration of CB in the system at steady-state, respectively.

The CB conversion over Ce-V-Ti catalysts with a different weight ratio of Ce was present in Fig.2(a). Ce(15)-V(2.5)-Ti catalysts performed a best catalytic activity in all catalysts. It can remove 58% CB at 150 ℃. However, the CB conversion over Ce-V-Ti catalysts with a higher or lower composition of Ce than 15Wt% were decline obviously. It indicated that adding too little of Ce had no obvious effect on improving the catalytic activity of CB combustion[8]. Meanwhile, excessive addition of active groups Ce would lead to agglomeration on the surface of Ti. It may reduce the catalytic activity by blocking the intermediate pore structure, reducing the specific surface area and active site on the surface of the catalyst[9].

The CB conversion over Ce-V-Ti catalysts with a different weight ratio of V was present in Fig.2(b). The CB conversion was improved obviously by adding a little of V ac co-activity content. In general, the amount of V added to commercial catalysts is between 0~4%. When 2.5% V was introduced into Ce(15)-Ti catalysts, the catalytic activity was effectively promoted. The order of catalytic activity at 200 ℃ was Ce(15)-V(2.5)-Ti> Ce(15)-V(2)-Ti> Ce(15)-V(5)-Ti> Ce(15)-V(10)-Ti. It indicated that VOx might aggrege on the surface of catalysts when adding much more V than 5 Wt%[9].

Fig.3(a) shows the XRD pattern of Ce-Ti, V-Ti and Ce-V-Ti catalysts. Among them, Ce-Ti and V-Ti catalysts were also prepared by sol-gel method, and the weight ratio of Ce/V was the same as that of Ce-V-Ti catalysts. The strong peak of anatase phase TiO2 (PDF 01-084-1286) was detected in all samples. There were no peaks corresponded to CeO2 and V2O5 because it’ s covered by strong support peaks of anatase and low crystallinity due to good dispersion of Ce and V on the surface of Ti. As we can see from Fig.3(b), the intensity of Ce-V-Ti at 23° ~28° was wider and shorter than Ce-Ti and V-Ti catalysts due to the solid solution reaction of Ce and Ti. The XRD pattern of TiO2 at (101) crystal plane shifted to the left (from 25.33° to 25.18° ). It indicated that the lattice constant “ a” (from 3.782 to 3.808 Å ) and the constant “ c” increased together (from 9.502 to 9.545 Å ) in the Ce-V-Ti catalysts. When the lattice constants “ a” and “ c” increased simultaneously, the chemical bond between metal elements and oxygen in the catalysts would become longer[10]. Solid solution of Ce4+ (atomic radius 1.14 Å ) with a larger atomic radius into Ti4+(atomic radius 0.61 Å ) would lead to lattice deformation of TiO2 with the bond length of Ti-Obeing longer. Hence, it would result in XRD patterns of TiO2 at (101) crystal plane shifted to the left in Ce-V-Ti catalysts [10].

Table 1 showed the specific surface area, pore volume and pore diameter of Ce-V-Ti catalyst. Surface and pore properties were changed with different metal oxides loaded on based-Ti. The SBET of V-Ti catalysts was 23.08 m2· g-1, which was the smallest one. When Ce is loaded, the specific surface area of the Ce-Ti catalysts increased to 90.53 m2· g-1. The specific surface area of Ce-V-Ti catalysts further increased to 95.53 m2· g-1 by introducing transition metal of V into Ce-Ti. It indicated that V made for the solid solution reaction of Ce into Ti[11]. It was consistent with the XRD results.

| Table 1 Surface and pore properties of Ce-V-Ti catalysts |

The information on the atomic concentration and element chemical state on the catalyst surface was investigated by XPS. Fig.4 (a— c) illustrated the obtained XPS spectra for Ce(3d), O(1s) and V(2p), respectively. As shown in Fig.4(a), the Ce(3d) spectra reveled that the Ce(3d) orbit was composed of two multiples (v and u). The u, u″, u‴, v, v″ and v‴ peaks were attributed to Ce4+ species, while u' and v' were assigned to Ce3+ species. During the recycle reaction of catalytic combustion, active oxygen species are released through reduction reaction of Ce4+→ Ce3+. Then Ce2O3 captures O from oxygen on the surface of catalysts, and re-oxidized to CeO2.

O(1s) spectra [Fig.4(b)] were deconvoluted into two contributions: one with binding energy (BE) of 529.3~529.8 eV was assigned to lattice oxygen (Oα ) and the other with BE of 531.0~531.4 eV (Oβ ) wasassigned to surface-adsorbed oxygen, such as

Fig.4(c) showed XPS curves of surface vanadium species. In Ce-V-Ti samples, V(2p3/2) level near 517.2 eV was ascribed to V5+ species and at 516.1 eV was assigned to V4+ species. V acted as a co-catalytic composition in CeO2/VOx catalysts. In the oxidation process, oxygen transferred from CeO2 to VOx and promoted the rate of a cyclic catalytic reaction. Appropriate V4+ icons in low valance were beneficial to improve the activity of the catalysts and ensure the electron transfer faster in the process of the mutual transformation of V4+ and Ce4+.

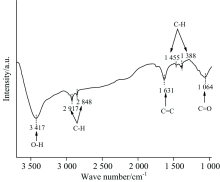

The Ce-V-Ti catalysts were analyzed by FTIR spectra, and the results were shown in Fig.5. The absorption band in the 3 200~3 700 cm-1 could be attributed to O— H stretching vibration in hydroxyl, carboxylic and phenolic groups. The adsorption bands at 1 610~1 680 cm-1 could be attributed to C=C stretching vibrations in carboxylic or pyridine-like structure. The bands at 1 050~1 160 cm-1 could be attributed to the bending vibrations of C=O groups. It could be seen that the FT-IR spectra of O— H (3 417 cm-1), C— H (1 388, 1 455, 2 848 and 2 917 cm-1), C=O (1 064 cm-1) and C=C (1 631 cm-1) surface functional groups existed in Ce-V-Ti samples. The strong peaks at 3 417 cm-1 were O— H functional groups. The aliphatic C— H groups at 1 388, 1 455, 2 848 and 2 917 cm-1 were the most peaks[12]. Both O— H and C— H groups were favored to the adsorption of CB on Ce-V-Ti catalysts and facilitated the desorption of CB. Generally, CB catalytic combustion mechanism over Ce-V-Ti catalyst is attributed Deacon Reaction and Mars van Krevelen (MVK) mechanism: chlorine of CB is adsorbed on the active metal site (Ce3+/Ce4+ and V3+). Chlorine abstraction by nucleophilic oxygen (basic lattice oxide ions or hydroxyl groups) to form phenolate intermediate. The active surface oxygen species attack aromatic ring, and the further effective reaction of oxygenating species to oxidize phenyl to CO2 and H2O, converted to Cl2 by Deacon Reactive. Thus, the CB conversion over Ce-V-Ti catalystscan be improved at low temperature by the functional groups.

(1) The Ce-V-Ti catalysts synthesized by sol-gel method showed excellent catalytic activity in a simulating iron ore sintering flue gas (CB: 100 ppm; 16% O2 and 84% N2; GHSV: 30 000 h-1; catalyst amount: 200 mg). The catalytic conversion of CB over Ce(15)-V(2.5)-Ti catalysts can achieve 58% at 150 ℃ and 95% at 300 ℃.

(2) Ce played a major catalytic role and V acted as a co-catalytic composition. The chemical interaction between Ce and Ti can improve the number of oxygen vacancies. The solid solution reaction of Ce into Tiwas promoted by adding V. V4+ can help to promote the reduction reaction.

(3) The specific surface area of the Ce-V-Ti catalysts was increased. It was favorable to the dispersion of the active components on the surface of Ti. Most of the functional groups on the Ce-V-Ti catalysts were C— H groups and O— H, which was expedited the adsorption and desorption of CB.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|