芝麻油是日常生活中常用食用油之一, 掺假芝麻油会导致严重的健康问题。 研究芝麻油鉴定方法是非常重要的。 皂化植物油提取不皂化物是食用油鉴定的经济方法之一, 现有植物油皂化方法需要较长时间, 较高的温度, 且不皂化物提取过程非常繁琐。 采用超声技术替代常规回流加热法, 提高了皂化效率, 皂化时间缩短至10分钟, 在此基础上采用专用固相萃取(SPE)小柱快速分离不皂化物。 基于分离富集得到的植物油不皂化物红外光谱, 结合化学计量学方法进行芝麻油鉴定。 利用偏最小二乘判别分析(PLS-DA)和正交偏最小二乘判别分析(OPLS-DA)构建芝麻油鉴定模型。 分析结果表明: 所构建的芝麻油鉴定模型, OPLS-DA模型优于PLS-DA模型; OPLS-DA模型对芝麻油检验集样本预测准确率高。 基于植物油不皂化物红外光谱结合化学计量学方法可以准确鉴定芝麻油。

Biography: HE Wen-xuan, female, (1962—), professor, Minjiang University e-mail: 706828346@qq.com

Sesame oil is one of the essential cooking oil, and it has been consumed in daily life. The intake of adulterated sesame oil leads to severe health problems. Thus the method to identify adulteration is significant research. Saponification is one of the simple and inexpensive processes have been used to identify the adulteration in edible oil. The saponification takes a long time, higher temperature and the isolation of unsaponifiable from saponifiable is tedious. In the present research, the enriched saponification process has been developed using ultrasonication technique instead of a common conventional method. The process has been significantly reduced to ten minutes. The special solid phase extraction (SPE) cartridge has been designed and prepared to separate the unsaponifiable. The combined FT-IR with chemometrics based on the isolated unsaponifiable was first used to authenticate sesame oil. The partial least squares discriminant analysis (PLS-DA) and orthogonal partial least squares discriminant analysis (OPLS-DA) was employed to establish the models to identify the adulteration detection and authentication of sesame oil. The results indicated that the OPLS-DA is better than PLS-DA, which was chosen for the authentication of sesame oil. The prediction of samples was accurate by the constructed model. The results suggested that the combined FT-IR spectroscopy with chemometrics based on isolated unsaponifiable could be used for authentication of sesame oil.

Worldwide, sesame oil is an ancient cooking oil that has been used from 2500 BC[1]. It is not only culinary oil and used as traditional medicine for curative, nutritive and preventive properties[2]. Due to increased demand of sesame oil, the need for sesame oil production is increased. For instance, the total production of sesame seeds in the world in 2016 was calculated to be 6.1 million tons[3]. And also about 2.1 million tons of sesame oil has been produced per year in China. The sesame oil contains potent components which have beneficial health effects like antioxidant, antibacterial and antiproliferative activities[4, 5, 6]. It is expensive oil than other vegetable oils like cottonseed oil, palm oil, soybean oil and corn oil. Thus, the adulteration of inexpensive oils with sesame oil is motivated by economic reasons in order to get the maximum profits. The intake of adulterated sesame oil may initiate harmful risks like cancer, paralysis and cardiac arrest. So the method for identifying the adulteration in sesame oil or authentication of sesame oil is significant research. Researchers have developed various methods for the discrimination of adulterated sesame oil[7, 8, 9, 10, 11, 12]. In general, chromatographic techniques like HPLC, GC, etc., and spectroscopic techniques like UV-Vis, FT-IR, NMR, Mass and Raman spectroscopies have been used to identify/quantify the adulteration of edible oil[13, 14]. The chromatographic and some of the spectroscopic techniques are expensive[15, 16, 17]. In the present study, the research is planned to develop a simple and cheaper process/analytical method for the authentication of sesame oil.

The sesame oil contains 98.5%~99.5% of saponifiable and 0.5%~1.5% of unsaponifiable[18]which has some characteristic absorbance strength. As varieties of plant oil like sesame oil, corn oil, soybean oil, palm oil and cottonseed oil differ marginally in the relative absorbance strength of the characteristic peaks in IR, it indicates that the amount of the main components in those oils may only have a slight difference. Thus, the isolation and characterization of unsaponifiable from edible oil would be more accurate to detect the adulterant. The unsaponifiable can be separated by chromatographical methods[12]. But these techniques are time-consuming and expensive. The common conventional saponification method[19] has a little drawback like longer process time, the necessity of high reaction temperature and separation of unsaponifiable is tedious. So there is a necessity to innovate the efficient saponification method and analytical technique for the isolation of unsaponifiable. Thus in the present report, the enriched saponification process has been developed using the ultrasonication technique[19] instead of conventional methods. For the separation of unsaponifiable, the special solid phase extraction (SPE) cartridge has been designed and prepared to isolate the unsaponifiable. To the best of our knowledge, this is the first report on the combined FT-IR and common chemometrics based on the isolated unsaponifiables to authenticate sesame oil. Finally, orthogonal partial least squares discriminant analysis (OPLS-DA) was employed to establish the models for the authentication of sesame oil, and obtained results were presented here.

All the chemicals and reagents were purchased from sinopharm chemical Co., Ltd. and Zhengzhou Tianxiang Inorganic Materials Co., Ltd. and used as without further purifications. P210 Ultrasound (Elma) sonicator was used for saponification reactions. Thermo Scientific Nicolet iS5 FT-IR Spectrometer was used to record the FT-IR spectra. Different varieties of plant oils were purchased in the local market.

The training set contains 54 samples that were purchased including 18 numbers of sesame oil (10 different brands), 18 numbers of corn oil (11 different brands) and 18 numbers of soybean oil (11 different brands). The fatty acid compositions of each plant oils were verified by gas chromatography (GB/T 17377— 2008). All their fatty acid compositions have agreed with Chinese National standards.

Testing set contains 35 samples were purchased/prepared including 12 numbers of sesame oil (10 different brands + 2 brands from a rural private convenience store), 8 numbers of adulterants (2 brands of palm oil, 2 brands of cottonseed oil, 2 brands of soybean oil and 2 brands of corn oil) and 15 numbers of adulterated sesame oil. The details of the test set were represented in Table I. The fatty acid compositions of each plant oils except adulterated sesame oil, sesame rural-Ⅰ and Ⅱ were verified by gas chromatography (GB/T 17377— 2008). All their fatty acid compositions have agreed with Chinese national standards.

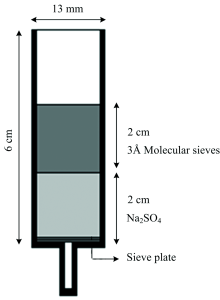

The solid phase extraction (SPE) tube (6 cm length× 1.3 cm diameter) was filled with 2 cm of 3 Å molecular sieves and 2 cm of anhydrous sodium sulfate. The bottom of the tube was closed by the sieve plate.

2 g of plant oil was mixed with 30 mL of 2 mol· L-1 ethanolic KOH (9:1, Ethanol:Water) and sonicated at 55 ℃ for 10 minutes. The ultrasonic power and frequency were fixed at 70% and 37 Hz correspondingly. After the completion of saponification, 35 mL of distilled water was added and extracted with 15 mL of n-hexane. The organic layer was separated, passed through the SPE cartridge and collected in the evaporating dish. The evaporation of n-hexane yielded pure unsaponifiable. The whole process was repeated to check the process is concordant.

The plant oils or unsaponifiable were loaded on the ATR-ID7 diamond crystal. The FT-IR spectra of the plant oils and unsaponifiable were recorded in the range of 3 300~700 cm-1. The spectra were recorded twice, and the absorbance results were reported from the mean values. The recorded vegetable oils and unsaponifiable spectra were converted to TXT format and plotted using Origin 8.5 pro software. The FT-IR of plant oils were automatically corrected by standard methods (baseline correction and normalized on the ordinate) and saved as CVS format. There are no further preprocessing steps performed using the SIMCA software. All the recorded data with CSV format were imported into Umetrics SIMCA15.0.2 software. There is a different range of wavenumber selected for plant oils (3 100~2 700 and 1 200~800 cm-1) and unsaponifiable (3 100~2 700 and 1 500~750 cm-1). On the basis of the sample’ s training set, the model was built by using PLS-DA and OPLS-DA. The score value range for the identification of sesame oil was set from the score value of the training set. The testing set score values were predicted from the selected model. Then, the sensitivity and specificity of the models were obtained.

The plant oils contain both saponifible and unsaponifible. For isolating the unsaponifiable from the plant oil and efficient saponification process is needed. Efficient saponification can be achieved by ultrasonic conditions. Various ultrasonic conditions were tried to complete the saponification with 2 mol· L-1 potassium hydroxide solutions. The conditions like temperature (40~80 ℃), ultrasonic frequency (37 and 80 Hz), time (5~30 min) and ultrasonic power (30%, 70% and 100%) were altered. Among various conditions, the saponification was completed in 10 minutes at 55 ℃. The ultrasonic power and ultrasonic frequency were fixed at 70% and 37 Hz correspondingly. More detail information above the selection of ultrasonic conditions was shown on reference [19]. The developed process is comparatively more efficient than previous literature report[20].

The unsaponifiable were extracted with n-hexane. In general, the trace of saponified long chain fatty acid salts is obtaining in n-hexane extraction which disturbs the characteristic absorbance in the IR spectrum. In some cases, the saponified long chain fatty acid salts are insoluble in water which affects the separation of the organic and aqueous layer. The multiple extractions are required with ethanol, water and hexane. The SPE cartridge was developed by using anhydrous sodium sulfate and molecular sieves. The anhydrous sodium sulfate absorbs the water molecules[21] and molecular sieves separate the inorganics and soap materials as well as absorb the water molecule[22]. For attaining good separation, various quantities of anhydrous sodium sulfate (1~3 cm), different quantities of molecular sieves (1~3 cm) were packed in the different SPE plastic tubes. Among various SPE cartridges, the 3 Å molecular sieves packed with 2 cm length and anhydrous sodium sulfate packed with 2 cm length provided the best effect. The advantage of the special SPE cartridge is which separates the residual alkaline substance as well as absorbs water in the organic phase in a single cycle and also economically inexpensive. The model image of the designed SPE cartridge is represented in Fig 1. The separated organic layer was purified by SPE cartridge. Information about the comparison between this method and GB/T 5535.2— 2008 was shown on reference [19].

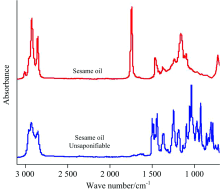

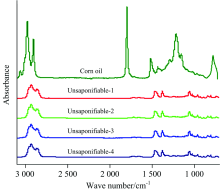

The completion of the saponification and quality of separation of unsaponifiable were proved by FT-IR spectroscopic technique. In general, the stretching vibration for carbonyl of gmycerides appears in the region of 1 740 cm-1. It has been identified as the characteristic peak for the presence of glycerides because the glycerides are absences in unsaponifiable. The FT-IR spectrum of plant oils showed a strong absorbance around 1 740 cm-1. In the isolated unsaponifiable, absorbance at 1 740 cm-1 was disappeared. Since polyunsaturated fatty acids in fats and oils will partly oxidize when heated in the air, producing very small amounts of short-chain aldehydes, ketones, acids and other small molecular compounds, these small molecular compounds could be extracted by hexane. Due to the induction effect, the peak wave number (1 740 cm-1) of the carbonyl absorption of fatty acid glyceride, the main component of the oil, was higher than that of the aldehyde and ketone, a slight absorption peak at 1 720 cm-1 has appeared in the isolated unsaponifiable. The FT-IR results clearly revealed that the plant oil was completely saponified and the separated unsaponifiable were free from soap components (the characteristic absorbance at 1 580 cm-1 is absent in the spectrum). The FT-IR spectra of various plant oils and their unsaponifiable were represented in Fig.2 and Fig.3. The saponification process was repeated four times with the same quantities of corn oil to check the reproducibility. The FT-IR spectra of various isolated unsaponifiable of corn oil with the above method were identical, which proved that the process is reproducible. The FT-IR spectra for 4 different unsaponifiable of corn oils were represented in Fig.4.

Soybean oil and corn oil are inexpensive which has often been used as an adulterant in sesame oil. In addition, the major components (saturated fatty acids, oleic acid and linoleic acid) of sesame oil, soybean oil and corn oil are strikingly similar. Thus, sesame oil, soybean oil and corn oil were chosen as samples for the training set. The composition of plant oil depends on the plant oil type, planting site and processing technique of oil. So multi brands of oils obtained from different processing technique was selected for the training set. The sensitivity and specificity of the model for discrimination of adulterated sesame oil or authentication of sesame oil is depending on the results of the testing set. So, it is very important to configure more practical samples in the testing set. 35 different samples for the testing set were prepared with or without adulteration. The inexpensive vegetable oils like cottonseed, palm, soybean, corn oil and their mixed oil were chosen as an adulterant. The adulterant quantity was selected as 4, 10 and 16% (adulterant/total oil, V/V) respectively. Sesame rural-Ⅰ and Ⅱ were used as blind samples.

From the FT-IR spectra of unsaponifiable, the model was constructed to discriminate the adulteration in sesame oil or to authenticate sesame oil. The spectral differences in five kinds of edible oil’ s unsaponifiable were identified in the range of 3 100~2 700 and 1 500~750 cm-1. And also the spectral data were stable in these regions. Thus these wavenumber regions were chosen for the construction of model Ⅰ (PLS-DA) and Ⅱ (OPLS-DA). The obtained results for both models were represented in Fig.5, which clearly showed that the slope of both fitting lines was greater than zero, the intercept of R2 was ≤ 0.3 and the intercept of Q2 was ≤ 0.05. So the model is reliable and not overfitted. Since model Ⅱ (R2=0.87; Q2=0.84; Component No=2) was better than the model Ⅰ (R2=0.86; Q2=0.82; Component No=3), which was chosen for authentication of sesame oil. The statistical significance confidence level is 95%. The core values of the sesame oil category for sesame oil in the training set were in the range of 0.88~1.06. So this range was used as the setting score value for sesame oil identification. On continuation, the score values for the testing set were predicted using model Ⅱ . The sensitivity and specificity of the model were derived from the results of the samples in the testing set. The predicted score value of the testing set was represented in Table 1. The results clearly showed that the 10 sesame oils were acknowledged as the sesame oil. Blind samples of the sesame rural-Ⅰ and sesame rural-Ⅱ were identified as fake oils for the score values were not in the range of 0.88~1.06. The GC of sesame oil rural-Ⅰ and Ⅱ also tested to prove the results were accurate. The GC results confirmed that the stearic fatty acid concentrations of sesame rural-Ⅰ and Ⅱ were both less than 4%, which did not meet the corresponding set value in the Chinese national standard for sesame oil. Other plant oils including 2 different cottonseed oil, palm oils, soybean oils and corn oils were detected as fake oils. Further, model Ⅱ clearly discriminated all the adulteration of soybean oil or palm oil or cottonseed oils with sesame oil. 10% and 16% adulterated corn oil or mixed oil with sesame oil also discriminated by this model (Table I. entry 23, 24, 32 and 33). Only 4% adulterated of corn oil or mixed oil with sesame oil (Table 1. entry 22 and 31) were inconvenient to discriminate by this model. The advantage of this model is the adulteration equal to 4% could be detected in most of the adulterated sesame oil. Overall, the model clearly discriminates the fake oils/adulterated sesame oil and also it has more sensitivity and specificity. The predicted score values of the testing set were represented in Table I and the sensitivity and specificity of model Ⅱ were represented in Table 2.

| Table 1 Score values of the testing set with model Ⅱ |

| Table 2 Predicted results of the testing set with model Ⅱ |

In order to facilitate comparison, the model to authenticate sesame oil based on FT-IR of the plant oils also constructed. In the plant oils FT-IR spectra, the spectral differences were identified in the region of 3 100~2 700 and 1 200~800 cm-1. And also the spectral data were stable in these regions. Thus the regions were selected to construct model Ⅲ (PLS-DA) and model Ⅳ (OPLS-DA). Similar to unsaponifiable’ s model, both the constructed models showed good robustness and no overfitting. Since model Ⅳ (R2=0.90; Q2=0.87; Component No=2) was better than model Ⅲ (R2=0.90; Q2=0.80; Component No=5), which was selected for discrimination of adulterated sesame oil or authentication of sesame oil. In Model Ⅳ , the score values of the sesame oil category for sesame oil in the training set were in the range of 0.80~1.05. So, this range was used as setting score value for the identification of sesame oil. The predicted score values of 35 samples of the testing set were represented in Table 3. This model successfully identified the 18 samples include 10 sesame oils and 8 inexpensive plant oils. But it was failed in the detection of most of the adulterated sesame oil and blind samples. For instance, blind samples of sesame rural-Ⅰ and Ⅱ were confirmed as sesame oil, but which were fake oil. 4% adulterated sesame oil (Table 3, Entry 19, 22, 28 and 31) were judged as sesame oil. Some of the adulterated sesame oil with 10% or 16% adulteration (Table 3, Entry 23, 24, 32 and 33) also failed to detect by this model. Further, it misidentified all the adulteration of corn oil and mixed oil with sesame oil. But countable adulterated sesame oils with 10% or 16% adulteration were successfully identified (Table 3, Entry 20, 21, 26, 27, 29 and 30). Further, it identified all the adulteration of palm oil with sesame oil. The reason for the failure of adulteration detection by model Ⅳ is the fatty acid composition of sesame oil and other plant oils except palm oil are strikingly similar, and the IR of plant oils mainly characterizes the fatty acid composition. The sensitivity and specificity of model Ⅳ were summarized in Table 4. Overall, model Ⅳ is poor to discriminate the adulterated sesame oil compared with model Ⅱ .

| Table 3 Score values of the testing set with model Ⅳ |

| Table 4 Predicted results of the testing set with model Ⅳ |

The enriched saponification process was developed using ultrasonication method and the new method was developed for the isolation of unsaponifiable from soap and inorganic materials. The saponification reaction time was successfully reduced to 10 minutes and quality of unsaponifible is highly pure. The disappearance of absorbance at 1 740 cm-1 in FT-IR spectra confirms the completion of the saponification. The isolated unsaponifiable IR spectrum has high quality and good reproducibility. Model Ⅱ was successfully constructed by OPLS-DA method using FT-IR spectra of isolated unsaponifiable for authentication of sesame oil. Model Ⅱ was compared with model Ⅳ using plant oil spectra. Model Ⅱ successfully identified the sesame oils, most of the adulterated sesame oils and blind samples. However, model Ⅳ was failed in the detection of most of the adulterated sesame oils and blind samples. It proves that the model Ⅱ is better for the authentication of sesame oil. The advantage of model Ⅱ is the adulteration equal to 4% could be discriminated in most of the adulterated sesame oil. The results concluded that the FT-IR spectroscopy combined with chemometrics based on isolated unsaponifiable could be useful to authenticate sesame oil.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|